Development of the support structure and transcatheter delivery system for the fully polymeric heart valve

Design extension of the novel fully polymeric heart valve for the long-term stability in mitral position and development of the tailored transcatheter delivery device

Project Team

- Jacopo Cossu, Doctoral Student

- Georgios A. Pappas

- Paolo Ermanni, Principal Investigator

Contact

Project Duration

2021 to present

Funding Sources

- CMASLab internal funding

- ETHeart initiative (of the Open ETH consortium)

- external pageZurich Heart projectcall_made of Hochschulmedizin Zürich

Project Description

During the last couple of years, CMASLab has devoted an important part of our research activity in a novel, fully synthetic, heart valve design. This design is based on a pioneer fiber reinforced composite stent, which has shown promise by respecting high durability and efficiency on the same time. This new design has also potential to replace heart valves with larger valvular orifice area, such as the tricuspid and the mitral valve. Moreover, it can act as a robust valve/valve-set for a total artificial implantable heart.

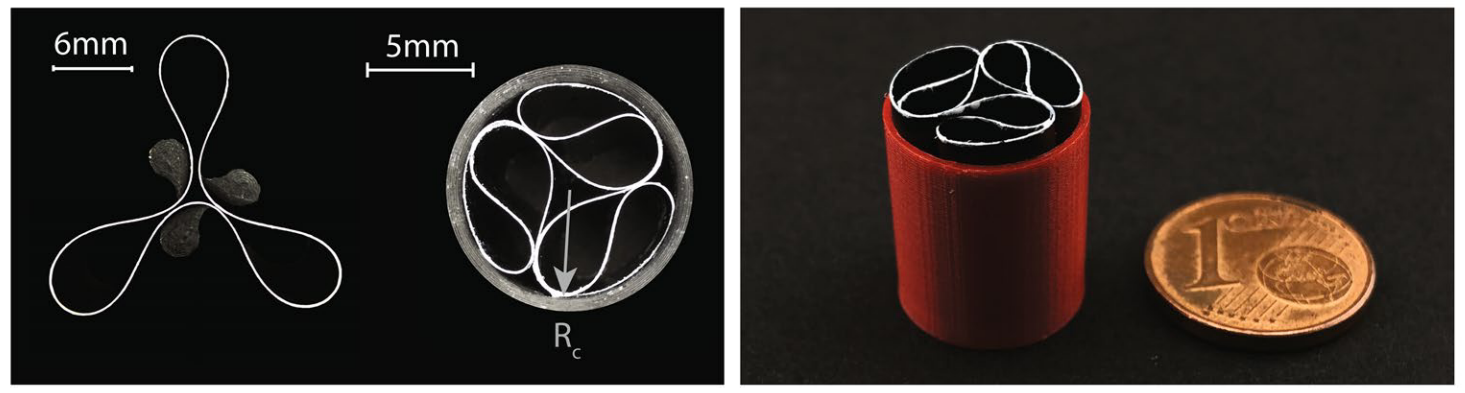

Among the four heart valves present in human heart, the aortic and mitral valves in the left side of the heart are most frequently affected by the valvular heart disease (VHD) due to the exposure to high pressure gradients required to pump the blood out to the systemic circulation. Epidemiological studies estimate approximately 70 million people suffering from VHD worldwide. With the state-of-the art transcatheter technology, the defective heart valves can be replaced with a prosthetic heart valve in a minimally-invasive fashion. The transcatheter replacement of the aortic valve has matured in the past 20 years after its first in-human implantation in 2002. However, transcatheter mitral valve replacement (TMVR) is at its infancy (first in-human implantation in 2012) and remains a huge challenge due to its geometrical complexity and high-pressure environment which impedes the long-term stability of the implant and increases the risk of dislodgment. To date, bioprosthetic heart valve (BPHV) is the only option for TMVR, which has poor durability (maximum 15 years) and high production cost. The novel fully polymeric heart valve (NFPHV) developed at CMASLab is a promising alternative to BPHV. Intrinsically high elasticity and expendability of the thin composite stent1 (Figure 1) allows the integration of NFPHV to the transcatheter technology. Furthermore, it has the potential to combine both high durability and excellent hemocompatibility, which has never been accomplished before in commercial heart valve implants.

This research aims to extend the design of the NFPHV to achieve stable anchoring and the high packing efficiency requirement for transcatheter delivery in mitral position. The concept of the deployable structures, such as ring pentograph or Daisy flower folding, and the anchoring elements will be integrated to the current design to increase the radial packing efficiency and the anchoring stability of NFPHV. The implant design will be optimized experimentally using a customized set-up to evaluate the anchoring stability and computationally by investigating the structural interaction between the mitral valve and the new implant design in silico. The customized set-up will contain a high-fidelity heart model based on the CT images of an actual patient’s heart (Figure 2), which mimics the mitral valve in terms of its anatomy and mechanical properties. In addition, a tailored transcatheter delivery device will be developed with a novel deployment concept to facilitate stable and controlled positioning of the NFPHV.

This project is conducted in collaboration with the Translational Cardiovascular Technologies (TCT) group of ETHZ and external pageDeutsches Herzzentrum Berlin - DHZBcall_made.

1Schlothauer, A. & Ermanni, P. Stiff Composite Cylinders for Extremely Expandable Structures. Sci. Rep. 9, (2019).