Durable thin-ply thermoplastic composites for shape adaptable structures

This research project involves developing the right processing conditions for manufacturing of thin ply thermoplastic composites with the objective of improving the durability of laminates when used in high-end applications.

Project Team

- Akshay Ramachandran, Doctoral Student

- Georgios Pappas, Senior Scientist

- Paolo Ermanni, Principal Investigator

Contact

Project Duration:

2021 to present

Funding sources

- CMASLab internal funding

- Airbus Defence and Space GmbH

Project Description

Challenge

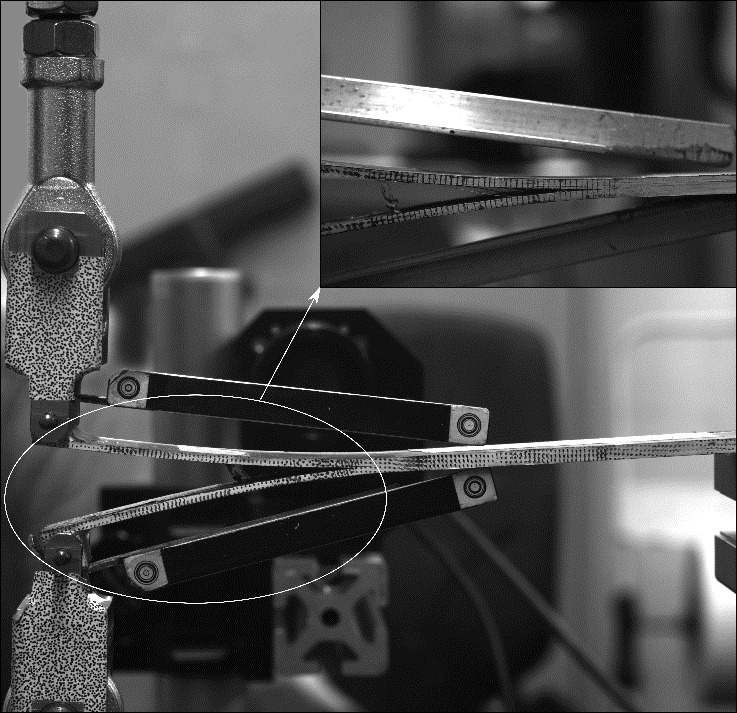

Thin ply thermoplastic composites add design freedom due to their very low ply thickness, inviting potential application of such materials in high-end applications such as flexible wings, biomedical devices and wearables. Using thermoplastic matrix over thermoset offers several advantages, in addition to the environmental reasons. However, in resisting interlaminar crack propagation, thin plies offer subpar performance than thick plies.

Aim of the research

This research project involves developing the right processing conditions for manufacturing of thin ply thermoplastic composites with the objective of improving the durability of laminates when used in high-end applications.

Methodology

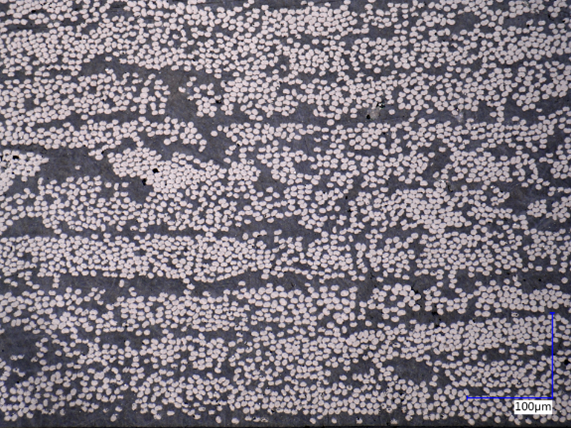

CMASLab has developed an in-house manufacturing technique for the fabrication of thin ply thermoplastic composites. Standardized experimental methods will be conducted to characterize the mechanical and damage properties. Furthermore, Finte Element based fracture mechanics would be implemented to model the mechanisms involved during crack propagation. Further studies are planned to tailor the damage tolerance during ply stacking.

This project is conducted in collaboration with Airbus Defence and Space GmbH.